Basic Information to Help You Figure out the Best Ball Bearings

Ball bearings are being used in various applications, from power transmission to manufacturing applications. Since these bearings are needed for such different applications, the market is flooded with different types. While buying these bearings, you need careful consideration of type, material, size, price, quality, coating, and many other factors of bearings. All these things will help you find the top-quality bearings for your application.

Factors to consider before buying Ball Bearings

- Type

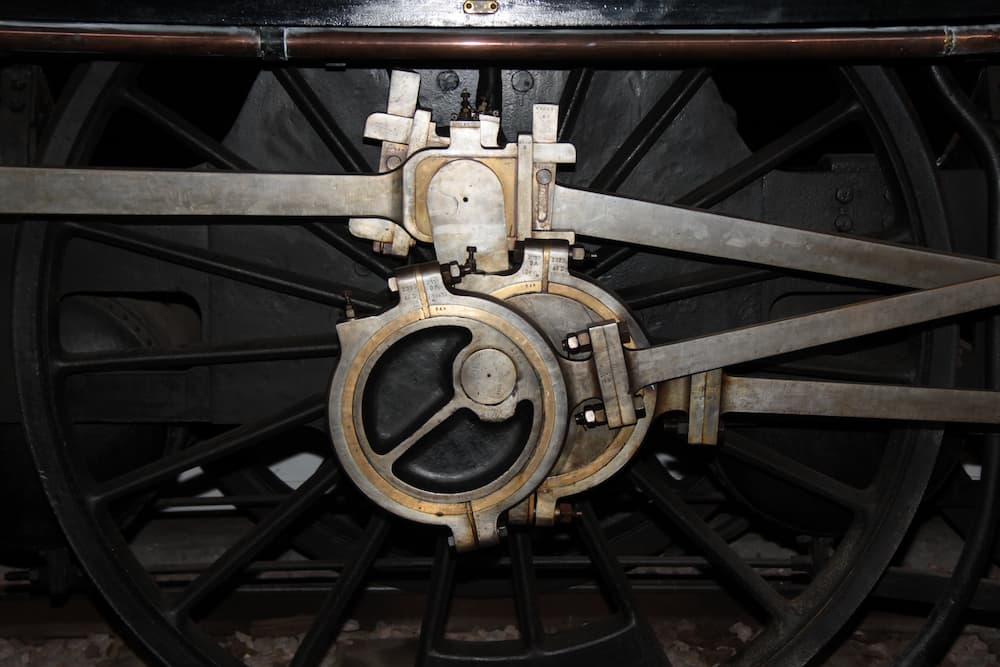

Due to wide applications, a huge range of types of ball bearings is available. These types include Thrust, Angular contact, Deep groove, Miniature, Self-aligning, linear & Mounted Bearings. Deep groove bearings are a common type. But you need to select a type according to your wok type.

- Bearing Runout & Rigidity

Bearing runout and rigidity is very important to determine the performance of bearing. For precise applications, small runouts are needed for tightness. Bearing rigidity is the resistance to the force that causes the shaft to deviate from its axis and plays a key role in minimizing shaft runout. It categorizes into two types: Axial & Radial rigidity. Remember higher the rigidity, the more force required to move the shaft.

- Size

The size of ball bearings is an important factor of consideration as it depends on its application. For most applications, an 8mm axle's size is being used. But many other sizes are also available in the market. Make sure to buy the appropriate size according to your use.

- Materials

The ball-bearing material plays a key role in minimizing the friction to its lowest. Most bearings are made of steel alloys with different coatings. Steel is affordable and tough material in bearings. Different coatings like bronze, ceramic, and titanium improve performance, durability, and resilience. Ceramic coating bearings are the best one among all. You can choose any type of your preference.

Benefits of Ball Bearings

Due to low friction, ball bearings provide high performance of its host instrument even during high speed and load. These ball bearings are designed to operate under extreme conditions without compromising on speed and performance. Because of this, ball bearings have different benefits:

- Ability to operate at a high range of temperature ( -40 to 180 degrees)

- Provide better sealing and prevent the leaking of lubricant.

- Easy to install

- Increase motor performance

- Easily available in market

- It can be used in a variety of applications

- Cost-effective solution

Frequently Ask Questions (FAQs)

What are the different grades of ball bearings?

The grades of the ball bearing determine its quality. The grade number of ball bearing means the tolerance/millionth of an inch. These grades have a different range. A grade of 25 is accurate to 25/1,000,000 of an inch. Cheap bearings may have 300 grades at 300/1,000,000 of an inch.

What is the hardest Ball bearing?

Steel ball bearings are the hardest of all types. This type is used as a standard with greater life ratings. It causes extremely low noise qualities to standard 440-grade stainless steel.

Conclusion

Because of the wide range of applications, many of us need to purchase ball bearings at some point in our work. If you want to buy ball bearings, make sure to buy a good quality product. A good quality ball bearing lasts long improves the performance of the machine/vehicle, and reduces noise production. Here we provide you with a complete list of high-quality ball bearings to make your choice easy. Make sure to read the complete list and find a product of your choice.